What is the crushing of the full-water coal sample

(PDF) Crushing properties of coal ResearchGate

Download full-text PDF Read full-text. sumption in the crushing of the coal sample and stan Coal samples, both lithotypes and whole channels, were selected from restricted rank ranges

Sampling and Sample Preparation Handbook of Coal

2015413 Recommended practices in coal crushing are: (1) incorporation of a screen to separate fines and small particles to avoid extra fine generation in crushing, and (2)

Coal Sample Preparation Procedures

201872 The purpose of sample preparation is to reduce and divide the original samples into test samples

Experimental Study of Coal Sample Damage in Acidic

2021812 The average strength of the coal samples soaked in solutions with pHs of 2, 4, and 6 was 4.5, 6, and 7.8 MPa, respectively, which is 60%, 80%, and 104% of the

(PDF) A Review on Steam Coal

20151213 0.1% of the weight of the sample being tested (for example, if samples being tested are expected

(PDF) Experience in coal sampling parameters calculation

2005111 After crushing, the grain class of steam coal -30+0 m m, The basic purpose of collecting and preparing a sample of coal is to provide a test sample which

Sources of underground CO: Crushing and ambient

2015111 In the four coal samples, the concentration of generated CO was inversely proportional to coal moisture content. Therefore, the moisture content in coal samples is

Effect of Bedding Structure on the Energy Dissipation

2021218 Figure 6 shows the dynamic tensile strength of coal samples with different bedding angles before and after water saturation. It can be concluded that when the

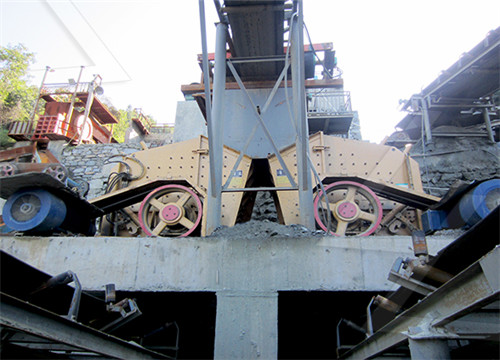

Coal comminution and sizing ScienceDirect

201311 Coal sizing: an introduction. After crushing with rotary breakers, crushing rolls, or other primary coal breakage machines, most coal processing plants will screen

(PDF) SIZE REDUCTION BY CRUSHING

201734 A laboratory analysis was also conducted using X-ray Fluorescence (XRF) analysis which shows that samples from Pit 1 to Pit 5 in the mine site at Kuru-Jentar

(PDF) Crushing properties of coal ResearchGate

2014121 Download full-text PDF Read full-text. sumption in the crushing of the coal sample and stan Coal samples, both lithotypes and whole channels, were selected from restricted rank ranges

Micro shape of coal particle and crushing energy

2018111 Each sample is put into a steel cylinder of 76 mm internal diameter and struck n times with a hammer of 2.4 kg falling through a distance of 0.6 m.n = 8, 13 and 18 represent impact energy applied on samples being 115.2, 187.2 and 259.2 J, respectively, assuming that the gravitational potential energy possessed by the piston before falling is

Experimental Study of Coal Sample Damage in Acidic

2021812 The average strength of the coal samples soaked in solutions with pHs of 2, 4, and 6 was 4.5, 6, and 7.8 MPa, respectively, which is 60%, 80%, and 104% of the 7.5 MPa of the samples soaked in distilled water. Coal samples in Group A exhibited the most strength degradation, the most damage caused by physical and chemical interactions

Study on the distribution pattern of particle re-crushing in

2022118 The change in the mean values of m p and m could reflect the crushing degree of the mixed coal samples in the loading process to a certain extent. Download: Li B B, Wang Z H, Ren C H, Zhang Y, Xu J. Research on mechanical properties and damage constitutive model of coal and rock under water-force coupling. Geotechnical mechanics.

Measuring the gas content of coal: A review ScienceDirect

199821 The coal sample is placed in a desorption canister containing stainless steel balls for subsequent crushing of the sample in the laboratory without having to transfer the sample to another container. The lost gas ( Q l ) is determined by the Umpl method ( Fig. 2 ) utilizing free flow desorption data points measured by the apparatus previously

Effect of coal particle size distribution, volume fraction and

2004315 The viscosity values of homogeneous coal–water samples containing particles of similar sizes are high irrespective of the rank of coal. The reason is that the relatively more homogenous second type of slurries containing particles of similar size, none being coarse, have relatively lower volume fraction values ( in all three different coals

(PDF) Experience in coal sampling parameters calculation

2005111 After crushing, the grain class of steam coal -30+0 m m, The basic purpose of collecting and preparing a sample of coal is to provide a test sample which when analyzed will provide the test

Effect of Bedding Structure on the Energy Dissipation

2021218 Figure 6 shows the dynamic tensile strength of coal samples with different bedding angles before and after water saturation. It can be concluded that when the bedding plane is perpendicular or parallel to the incident direction (that is, the bedding angle is 0 or 90 degrees), the test results before and after water absorption are more concentrated

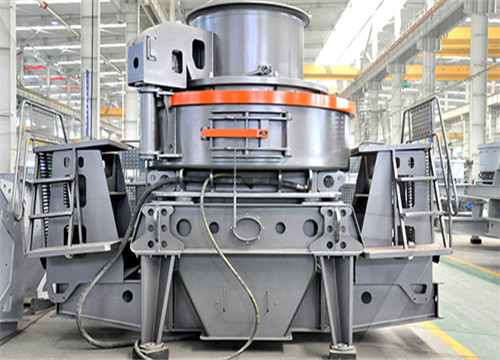

Crushing in Mineral Processing

20151226 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely

(PDF) SIZE REDUCTION BY CRUSHING

201734 A laboratory analysis was also conducted using X-ray Fluorescence (XRF) analysis which shows that samples from Pit 1 to Pit 5 in the mine site at Kuru-Jentar

Micro shape of coal particle and crushing energy

2018111 Each sample is put into a steel cylinder of 76 mm internal diameter and struck n times with a hammer of 2.4 kg falling through a distance of 0.6 m.n = 8, 13 and 18 represent impact energy applied on samples being 115.2, 187.2 and 259.2 J, respectively, assuming that the gravitational potential energy possessed by the piston before falling is

Experimental Study of Coal Sample Damage in Acidic

2021812 The average strength of the coal samples soaked in solutions with pHs of 2, 4, and 6 was 4.5, 6, and 7.8 MPa, respectively, which is 60%, 80%, and 104% of the 7.5 MPa of the samples soaked in distilled water. Coal samples in Group A exhibited the most strength degradation, the most damage caused by physical and chemical interactions

Effect of coal particle size distribution, volume fraction and

2004315 The viscosity values of homogeneous coal–water samples containing particles of similar sizes are high irrespective of the rank of coal. The reason is that the relatively more homogenous second type of slurries containing particles of similar size, none being coarse, have relatively lower volume fraction values ( in all three different coals

Study on the distribution pattern of particle re-crushing in

2022118 The change in the mean values of m p and m could reflect the crushing degree of the mixed coal samples in the loading process to a certain extent. Download: Li B B, Wang Z H, Ren C H, Zhang Y, Xu J. Research on mechanical properties and damage constitutive model of coal and rock under water-force coupling. Geotechnical mechanics.

Measuring the gas content of coal: A review ScienceDirect

199821 The coal sample is placed in a desorption canister containing stainless steel balls for subsequent crushing of the sample in the laboratory without having to transfer the sample to another container. The lost gas ( Q l ) is determined by the Umpl method ( Fig. 2 ) utilizing free flow desorption data points measured by the apparatus previously

Effect of Bedding Structure on the Energy Dissipation

2021218 Figure 6 shows the dynamic tensile strength of coal samples with different bedding angles before and after water saturation. It can be concluded that when the bedding plane is perpendicular or parallel to the incident direction (that is, the bedding angle is 0 or 90 degrees), the test results before and after water absorption are more concentrated

Dynamic tensile properties, deformation, and failure

2021329 Disc coal samples with different water content were tested using the split Hopkinson press bar test system. Their dynamic tensile failure process was monitored via an ultra-high-speed digital

(PDF) SIZE REDUCTION BY CRUSHING

201734 A laboratory analysis was also conducted using X-ray Fluorescence (XRF) analysis which shows that samples from Pit 1 to Pit 5 in the mine site at Kuru-Jentar

Mechanical response and gas flow characteristics of pre

202321 Vertically, four distinct vertical bands of coal permeability can be found in the EMOB, SQB and WGP, defined by the compression and deformation of the coal-matrix under certain stress regimes: in

Influence of Coal Type on Water Spray Suppression of

2022221 One-pound coal samples were pre- pared by crushing the underground run- of-mine coal to -1/4 inch (0.635 cm) and reducing the collected sample amount with a conventional chute splitter (riffle). This procedure was used to increase the con- sistency of the coal feed used for dust generation. The repeatability of the labo-