3 rollers vertical coal mill in cement plant

Coal Mills for Cement Plants Loesche

2023214 LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard

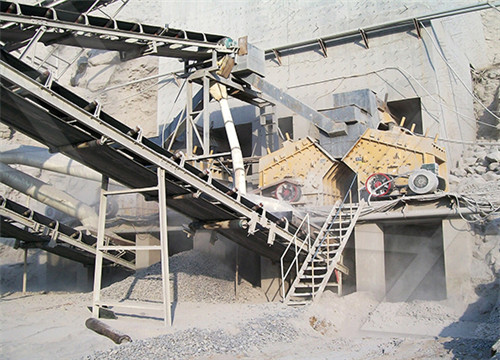

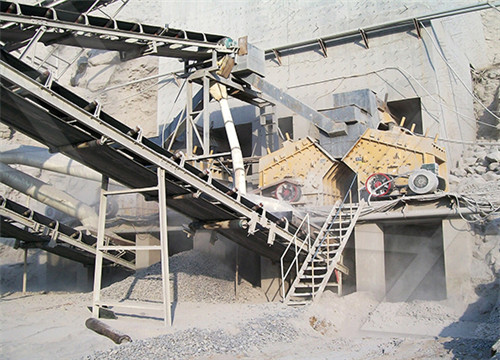

Vertical Coal Mill for Coal Grinding in Cement Plant

Vertical Coal Mill. Feeding size: ≤110mm. Capacity: 5-70t/h. Motor power: 110-1400kW. Applications: Vertical coal mill is mainly used for grinding raw coal, bituminous coal, and

(PDF) Performance Evaluation of Vertical Roller Mill in

2017911 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg. Samples were collected from mill inside and

Vertical Cement Mill, Vertical Roller Mill AGICO Cement

2023214 The vertical works according to the principle of layer material to powder. Low energy, the powder consumption of vertical mill is 20%-30% less than that of ball

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process.In recent years, the VRM cement

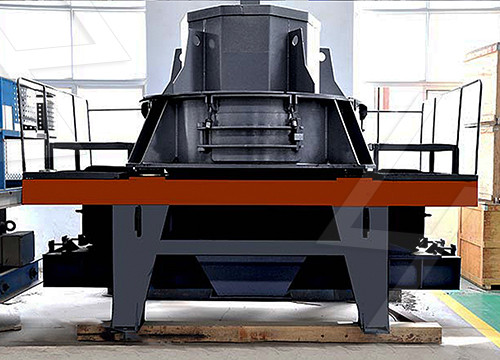

Vertical Cement Mill Cement Clinker Grinding Equipment

Vertical Cement Mill. Feeding size: ≤110mm. Capacity: 55-250t/h. Motor power: 1250-5300kW. Applications: It mainly used in the cement clinker grinding section of cement

PROCESS CONTROL FOR CEMENT GRINDING IN

20171027 factors and controller design for cement grinding are discussed in [37]. Figure-1. Vertical roller mill for cement grinding [13]. VRM shown in Figure-1 uses

3 Rollers Vertical Coal Mill In Cement Plant

2021101 7. 8. 9 Mills for Cement and The Loesche vertical mill is characterised by the fact that several processes comminution, dry-Coal Vertical Roller Mill Chaeng

3 rollers vertical coal mill in cement plant

Thailand: Siam Cement has ordered a LM 56.3+3 CS vertical roller mill from Loesche for its cement plant in Kaeng Khoi. The mill will produce It is designed to grind 80t.hr of coal to

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energy-efficiency. Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs.

Coal Mills for Cement Plants Loesche

2023214 LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard

Vertical Coal Mill for Coal Grinding in Cement Plant

Vertical Coal Mill. Feeding size: ≤110mm. Capacity: 5-70t/h. Motor power: 110-1400kW. Applications: Vertical coal mill is mainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is supplied to rotary kiln and other kilns in the cement plant and thermal power plant. Email: info@ballmillssupplier.

(PDF) MPS mills for coal grinding researchgate.net

201411 Two mill systems are employed for most coal grinding applications in the cement industry. These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on

Review on vertical roller mill in cement industryits

202111 Now a days Cement plants are producing 75–80% PPC20–25% OPC due to high market demand of PPC. Production of PPC is cheaper and it's market rate is also lower than OPC by nearly 25 rupees per bag, so general consumer are attracted towards PPC cement. Cement companies also want to produce more and more PPC grade.

(PDF) Performance Evaluation of Vertical Roller Mill in

2017911 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg. Samples were collected from mill inside and around the circuit to evaluate the

en/rollers vertical coal mill in cement plant.md at main

. Contribute to sbmboy/en development by creating an account on GitHub.

Vertical Cement Mill Cement Clinker Grinding Equipment

Vertical Cement Mill. Feeding size: ≤110mm. Capacity: 55-250t/h. Motor power: 1250-5300kW. Applications: It mainly used in the cement clinker grinding section of cement manufacturing process. Well grinding for slag, cement raw material and other materials. Email: info@ballmillssupplier. Now.

Cement Vertical Roller Mill

1 500 t/d Cement Plant; 700 t/d Cement Plant; 1000 t/d Cement Plant; 1500 t/d Cement Plant; 2500 t/d Cement Plant; 3000 t/d Cement Plant; 2*3000t/d Cement Plant of Meng Electric Cement Co., Ltd. 4500t/d Cement Line of Tailong Building Materials Co., Ltd. 5000 t/d Cement Plant of Deng Electric Group Cement Co., Ltd. GGBFS Turnkey Line;

3 Rollers Vertical Coal Mill In Cement Plant

2021101 7. 8. 9 Mills for Cement and The Loesche vertical mill is characterised by the fact that several processes comminution, dry-Coal Vertical Roller Mill Chaeng Cement Amp Mining. It is widely used in Cement Plant, Steel Mill, Thermal Power Plant ,electricity field, metallurgy sector, building material industry, chemical industry, etc.

github

3 rollers vertical coal mill in cement plant. working vertical roller coal mill in cement plant. 3 rollers vertical coal mill in cement plant.Standalone Vertical Roller Mills with

Coal Mills for Cement Plants Loesche

2023214 LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard

Vertical Coal Mill for Coal Grinding in Cement Plant

Vertical Coal Mill. Feeding size: ≤110mm. Capacity: 5-70t/h. Motor power: 110-1400kW. Applications: Vertical coal mill is mainly used for grinding raw coal, bituminous coal, and other fuels into coal powder, which is supplied to rotary kiln and other kilns in the cement plant and thermal power plant. Email: info@ballmillssupplier.

(PDF) Performance Evaluation of Vertical Roller Mill in

2017911 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg. Samples were collected from mill inside and around the circuit to evaluate the

(PDF) MPS mills for coal grinding researchgate.net

201411 Two mill systems are employed for most coal grinding applications in the cement industry. These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on

Vertical roller mill services

The vertical roller mill (VRM) is firmly established in cement plants all over the world. The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioning.

Vertical Cement Mill Cement Clinker Grinding Equipment

Vertical Cement Mill. Feeding size: ≤110mm. Capacity: 55-250t/h. Motor power: 1250-5300kW. Applications: It mainly used in the cement clinker grinding section of cement manufacturing process. Well grinding for slag, cement raw material and other materials. Email: info@ballmillssupplier. Now.

en/rollers vertical coal mill in cement plant.md at main

. Contribute to sbmboy/en development by creating an account on GitHub.

Cement Vertical Roller Mill

1 500 t/d Cement Plant; 700 t/d Cement Plant; 1000 t/d Cement Plant; 1500 t/d Cement Plant; 2500 t/d Cement Plant; 3000 t/d Cement Plant; 2*3000t/d Cement Plant of Meng Electric Cement Co., Ltd. 4500t/d Cement Line of Tailong Building Materials Co., Ltd. 5000 t/d Cement Plant of Deng Electric Group Cement Co., Ltd. GGBFS Turnkey Line;

3 Rollers Vertical Coal Mill In Cement Plant

2021101 7. 8. 9 Mills for Cement and The Loesche vertical mill is characterised by the fact that several processes comminution, dry-Coal Vertical Roller Mill Chaeng Cement Amp Mining. It is widely used in Cement Plant, Steel Mill, Thermal Power Plant ,electricity field, metallurgy sector, building material industry, chemical industry, etc.